The Allston is the first Montague folding bike to offer a carbon belt drive in place of a traditional chain. The Gates belt combined with a Shimano Alfine 11 speed internal gear hub provides a quiet, clean, and nearly maintenance free drivetrain.

Proper tension on the belt is very important, as it ensures the system is as efficient as possible and has the longevity belts are famous for. A new Montague Allston will arrive with the belt pre-tensioned, and since the bike uses vertical dropouts the rear wheel can be removed and replaced for tire changes without loosening belt tension. However, it’s good to know how to make these adjustments if necessary.

Belt tension is achieved through the use of an eccentric bottom bracket. The bearing cups are fitted into a larger cylindrical plug, which can rotate in the frame’s bottom bracket shell. The bearing cups are off center, so rotating the whole units moves the crankset forward and backward relative to the rear wheel.

To make an adjustment, you will need a 5mm allen key to loosen the eccentric BB.

From the non-drive side of the bicycle, insert the allen key into the center hole on the side of the eccentric BB. Make sure it’s pushed all the way in and seated in the recessed bolt. When attempting to turn it, you should feel resistance.

Loosen the bolt securing the BB by turning it counter clockwise.

With that bolt loose, It’s now possible to rotate the entire unit. You can get leverage by engaging two of the holes on either side of that bolt. This can be easily done with a freewheel pin spanner, in this case a Park Tool SPA-1.

The end of each prong can fit into the two outermost holes and allow you to rotate the BB. With it in this position, rotating counterclockwise will move the crank toward the back of the bike and loosen the belt tension, while rotating clockwise will move the crank toward the front of the bike and tighten the belt.

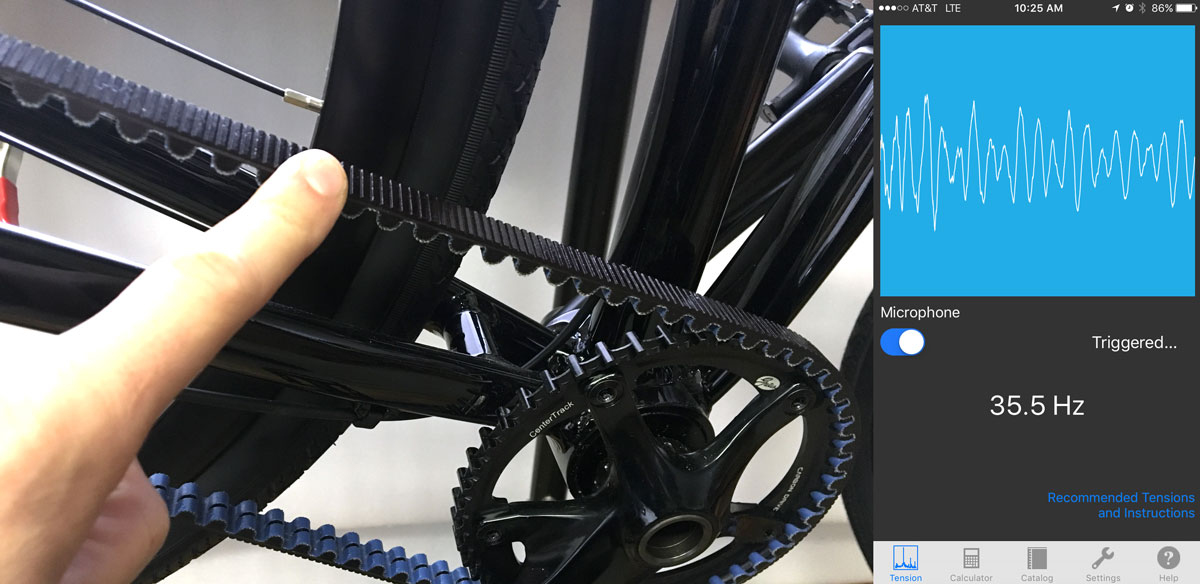

Gates provides two ways to check belt tension; a special tool you can purchase or a free app you can download to any smartphone. The app uses your phone’s microphone to measure the frequency of the sound made from plucking the belt. Just like a guitar string, the tighter the belt the higher the frequency.

With the app open, position your phone near the belt and pluck the center. You should hear the vibration which will be recognized and measured by the app. For internal gear hubs Gates recommends 35 – 50 Hz, which translates to 28 – 40 lbs of tension.

When you have the desired belt tension, be sure to re-tighten the bolt recessed in that center hole on the non-drive side. Insert the 5mm allen key back in the whole, and turn clockwise. Now you’re ready to ride!

Would love to have one,start a new tren in Cali. Msybe you guys can make thst happen ill be a ambassador.

Thorn has been doing this for years…

Yes, it is one of the most common ways of tensioning a belt drive bike.

I love belt driven bikes in theory. I have had three belt driven bikes and none of them worked. The lbs ended up putting a chain on the last one after they gave up.

Can somebody tell me if I should tight the eccentric in the same direction wich the crankset move to ride the bike, or the opposite ?

The question seems stupid, but in some situations the rotation of the spheres tend to rotate the bottom bracket in opposite direction of the crankset spinning.

Sorry from my english, I’m portuguese. Thanks.

Rotating the BB in the same direction as the cranks turn when pedaling should loosen belt tension. Rotating in the opposite direction of pedaling should tighten the belt.

Hello. QUESTION: We’ve followed the above instructions but are still not having any luck rotating the eccentric BB. Have all the required tools. If I try to tweak the SPA-1 any harder I will break it. Is there a trick to loosening the BB other than loosening the 5mm hex bolt? Please advise. Thank you.

I usually have to loosen the 5mm hex bolt and then give it a little whack with a hammer to unseat the wedge it screws into. Hope that helps

Just received a Marin Belt bike at our shop “Damn Good Bikes ” in Tallahassee Florida. Looks and rides well and like the concept.

Would i be able to upgrade my belt to this gates carbon on my paratrooper frame?

Since a belt cannot be broken and put back together like a traditional bike chain, a frame needs to be designed specifically for belt drive use. A removable dropout or a split in the seatstay is usually used to allow installation of the belt. The only frame we make with this feature is the Allston so unfortunately a belt cannot be added to the Paratrooper.

If you are running an internally geared hub on your paratrooper already then Veer makes a split belt conversion kit that doesn’t require a split frame. They don’t have all their sprockets up on the website but if you contact them they can make you a custom one. There are examples on their instagram. https://www.veercycle.com/

Good afternoon! Is it possible with such an eccentric to increase the star on the rear wheel, for example: it was 32T and put 34T, can the eccentric compensate for the installation of a larger star. Thanks a lot!

Hi Vladimir. If you have a bike that currently uses an eccentric bottom bracket, it might have enough adjustment built in to accommodate a different size rear cog. If can’t adjust enough, then you would need to use a different size belt, or longer chain, depending on what your bike uses.

If the bike doesn’t currently have an eccentric BB, then installing one is a challenge. The frame normally has to be built with a special BB shell in order to accommodate it.

The manual says to loosen all 3 hex bolts at the BB. Do I need to do that to be able to rotate the BB? If so, how much do I loosen them? Do I take them all the way out? Thanks. Is there a video tutorial showing how to adjust tension? (My new Allston belt tension is measuring at 74 Hz and squeaks when in use. )

Bought my Allston in October 2023. Over time it developed a creak/squeak when pedaling normally. It would never do it at the start of a ride but after ~10 minutes it would start. Sound seemed to come from the crank area. Took it to the shop where I bought it and they thought it was the pedals. Replaced the Wellgo pedals with MKS pedals. Might have been a bit better but still some creak/squeak. Replaced those pedals with Kootu pedals. No improvement. Then noticed the Gates belt seemed really tight. Didn’t bother with the Gates app since the reviews said it was worthless using the pluck/vibrate analysis and instead bought their Krikit belt tension gauge. The gauge showed an average tension of 75 lbs (should be 28-40). I loosened it up per the instructions in the owners manual. Now I have the tension at 30 lbs and the creak/squeak is completely gone!

I bought the bike new and the only way I can guess the belt got too tight was 1) overtightened at the factory, 2) Rackstand had to be replaced because it was bent during shipment so either the bang that bent the Rackstand or the replacement process led to tightening of the belt, or 3) my bike tipped once on a windy day when the Rackstand wasn’t able to keep it upright and if the pedals got knocked just so maybe the belt ended up tighter. In any case, I’m glad I figured out the cause of a very annoying squeak on my high end bike. The adjustment was also surprisingly easy with a 3 mm allen wrench and a hammer (and the Krikit gauge).

Does the Allston freewheel conform to the BCD104 format?

The Allston “chainring” (although there’s no chain so it’s often called a “front drive ring”) does have a bolt circle diameter of 104mm.

My new Allston (April 2024) came with a YST eccentric BB, different from the one in the pictures above.

I found instructions that said to loosen all 3 hex bolts and then tap on the hex wrench to break them loose. Then put a hex wrench, screw driver or whatever will fit all the way through the larger open holes and use another screw driver to leverage the BB around.

Here’s a link with photos…